Produktübersicht

HIGHLIGHTS

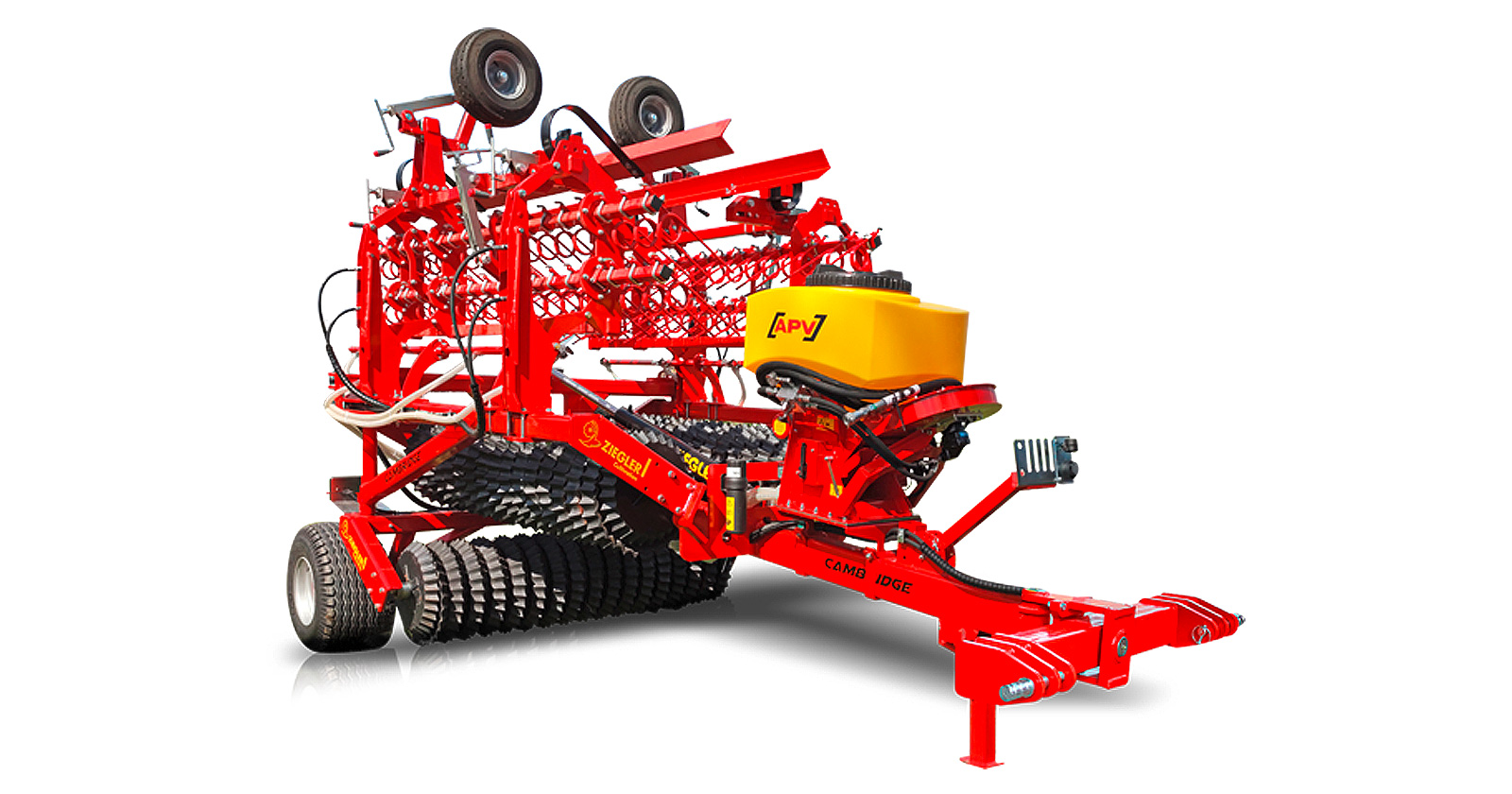

Nahezu alle ZIEGLER CULTIVATION-Maschinen können mit Streuern ausgerüstet werden. Die Sägeräte decken nahezu alle Anwendungen in der modernen Landwirtschaft ab. Die präzise Dosierung erfolgt über eine Säwelle. Die bodennahe Ausbringung über Schläuche und Prallbleche verspricht eine exakte Ablage von Begrünungen, Untersaaten, Grasnachsaaten und vielem mehr.

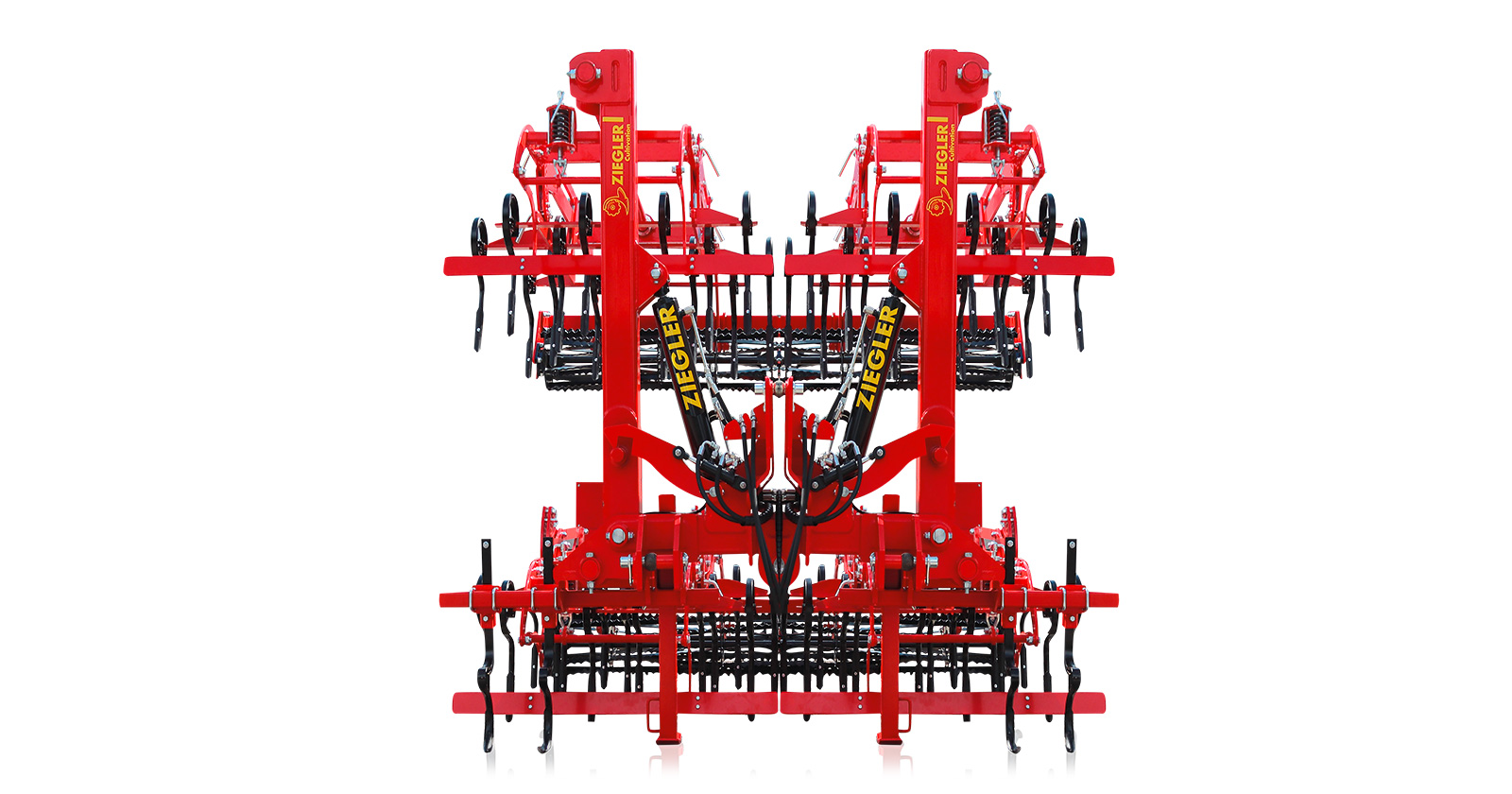

ZIEGLER hat momentan sieben Walzentypen im Programm: Die offene Stabwalze, die Dachringwalze, der Federstempelwalze, die Stahlringwalze, U-Profil- und Doppel-U-Profil-Walzen und eine Doppelkrümler-Walze.

Je nach Boden (leicht, mittel, schwer) bieten wir unterschiedliche Schare und Spitzen an. Von der Standardversion bis zur Heavy-Duty-Ausführung mit höchstmöglicher Härte für maximale Lebensdauer.

Hektarzähler oder Betriebsstundenzähler gibt es als Nachrüstsatz oder bereits ab Werk an Maschine montiert.